Propulsion, Turbomachinary and Combustion

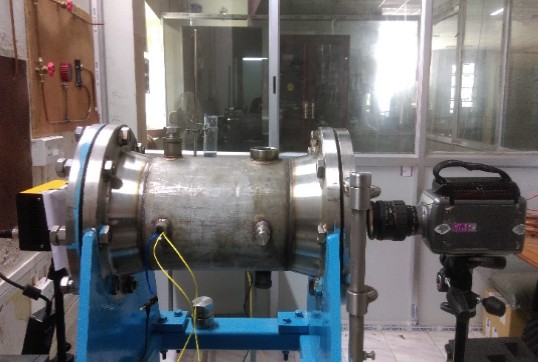

The Combustion and Turbomachinery research group at IIT Kharagpur explores a diverse range of topics with a variety of approaches. Specific areas of research include single droplet and spray combustion of alternative fuels, laser diagnostics of combustion process (characterization of a laser induced spark and its efficacy in the ignition of combustible mixture and on wave drag reduction), combustion of solid fuels and propellant (for rocket applications), single and multiphase fluid dynamics, chemically reacting flows, design and performance augmentation strategies for turbomachines, experimental and computational studies of turbomachines.

A new experimental facility on laser ignition of liquid fuel spray-air mixture, combustion spectroscopy, spray combustion of liquid fuels and multi-hole probe calibration have been developed. In the numerical simulations, the ongoing efforts are to improve the spatial accuracy to fourth order of a compressible chemically reacting flow solver (developed in-house) which will be used for studies on LES of combustion.

Current research activities include: Investigation on Combustion Characteristics of n-Butanol & Butyl Butyrate for their Application as Potential Aviation Fuels, Investigation on Spray Combustion Characteristics of JP-10 Embedded with Boron Particles, Investigation on the Distribution of Absorbed Energy After a Laser Induced Breakdown in Quiescent Air, Aerodynamic design of traction rolling stock with speed potentials of 250 km/h upgradeable up to 350 km/h, Experimental Investigations on Performance of Tandem Bladed Low Speed Axial Flow Compressor, Design and development of ICING tunnel for turbomachines research.

A new experimental facility on laser ignition of liquid fuel spray-air mixture, combustion spectroscopy, spray combustion of liquid fuels and multi-hole probe calibration have been developed. In the numerical simulations, the ongoing efforts are to improve the spatial accuracy to fourth order of a compressible chemically reacting flow solver (developed in-house) which will be used for studies on LES of combustion.

Current research activities include: Investigation on Combustion Characteristics of n-Butanol & Butyl Butyrate for their Application as Potential Aviation Fuels, Investigation on Spray Combustion Characteristics of JP-10 Embedded with Boron Particles, Investigation on the Distribution of Absorbed Energy After a Laser Induced Breakdown in Quiescent Air, Aerodynamic design of traction rolling stock with speed potentials of 250 km/h upgradeable up to 350 km/h, Experimental Investigations on Performance of Tandem Bladed Low Speed Axial Flow Compressor, Design and development of ICING tunnel for turbomachines research.

Facilities

Bomb Calorimeter

- Exact composition of practical fuels is often not known

- Determination of heating value (HV) is important

- Familiarize the students how to use Bomb calorimeter to determine HV

- Measure the HV of a solid fuel (such as wax) and compare the value available in literature

Droplet Combustion

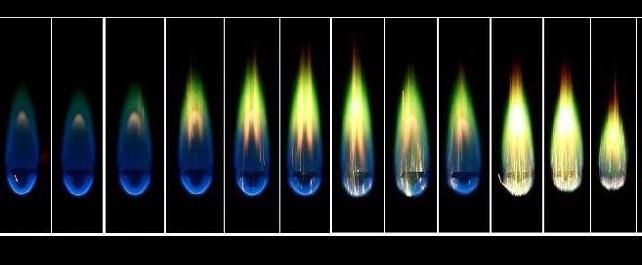

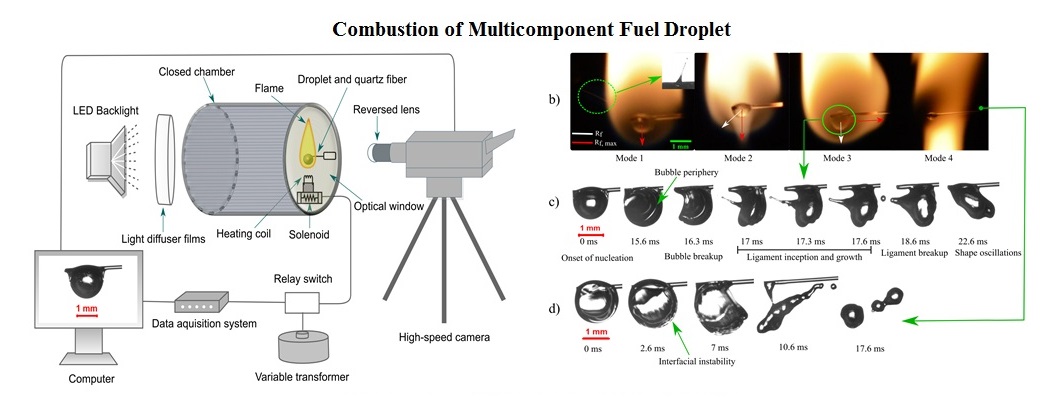

- The combustion of a multicomponent fuel with higher volatility differential leads to the disruptive phenomena such as puffing and micro-explosion.

- The fragmentation caused by micro-explosion and puffing plays an important role in accelerating spray atomization in the combustion chamber, which can be considered as an effective way of promoting efficient combustion.

Educational Gas Turbine Jet Engine

- A complete laboratory-based Turbojet engine demonstration unit.

- Provision for measurement of pressure and temperature at several locations of the engine as well as engine speed and thrust.

Flame Propagation and Stability Unit

- Flame Lift Off, Flame Light Back

- Provides data for the construction of flame stability diagrams

- Enables students to investigate methods of improving flame stability limits

- Allows investigation of the relationship between flame speed and air – fuel ratio for a variety of slow burning gaseous fuels

Ramjet Engine Test Stand

- Demonstration and investigation of the ramjet principle.

- Total and static pressure plots along the ramjet engine axis

- Comparison of Propane with other gaseous fuels, e.g. Acetylene, Butane, Methane (To be augmented)

- Complete performance analysis at various approach speeds. Calculation of exhaust velocities, measurement of temperatures, thrust, specific thrust, drag and fuel consumption (Needs to be upgraded)

Experimental Impulse Turbine Unit

- Visual examination of a small impulse turbine

- Production of torque/speed and power/speed curves from the experiments

- Comparison of turbine performance including specific air consumption when using throttle control or nozzle(4) control

- Determination of the isentropic efficiency of a turbine and plotting the end states on a T-s diagram

Experimental Reaction Turbine Unit

- Visual examination of a small reaction turbine

- Torque speed / power speed curves from a no load speed exceeding 35000 rpm to stall for wide range of inlet pressures

- Evaluation of specific air consumption at a range of speeds and pressures

- Determination of isentropic efficiency

Nozzle Performance Test Unit

- Visual examination of nozzle choking

- Determination of the effect of inlet and back pressure on mass flow rate through nozzles

- Measurement of the velocity of a jet issuing from a nozzle operating at a variety of inlet and back pressures

- Calculation of nozzle efficiencies

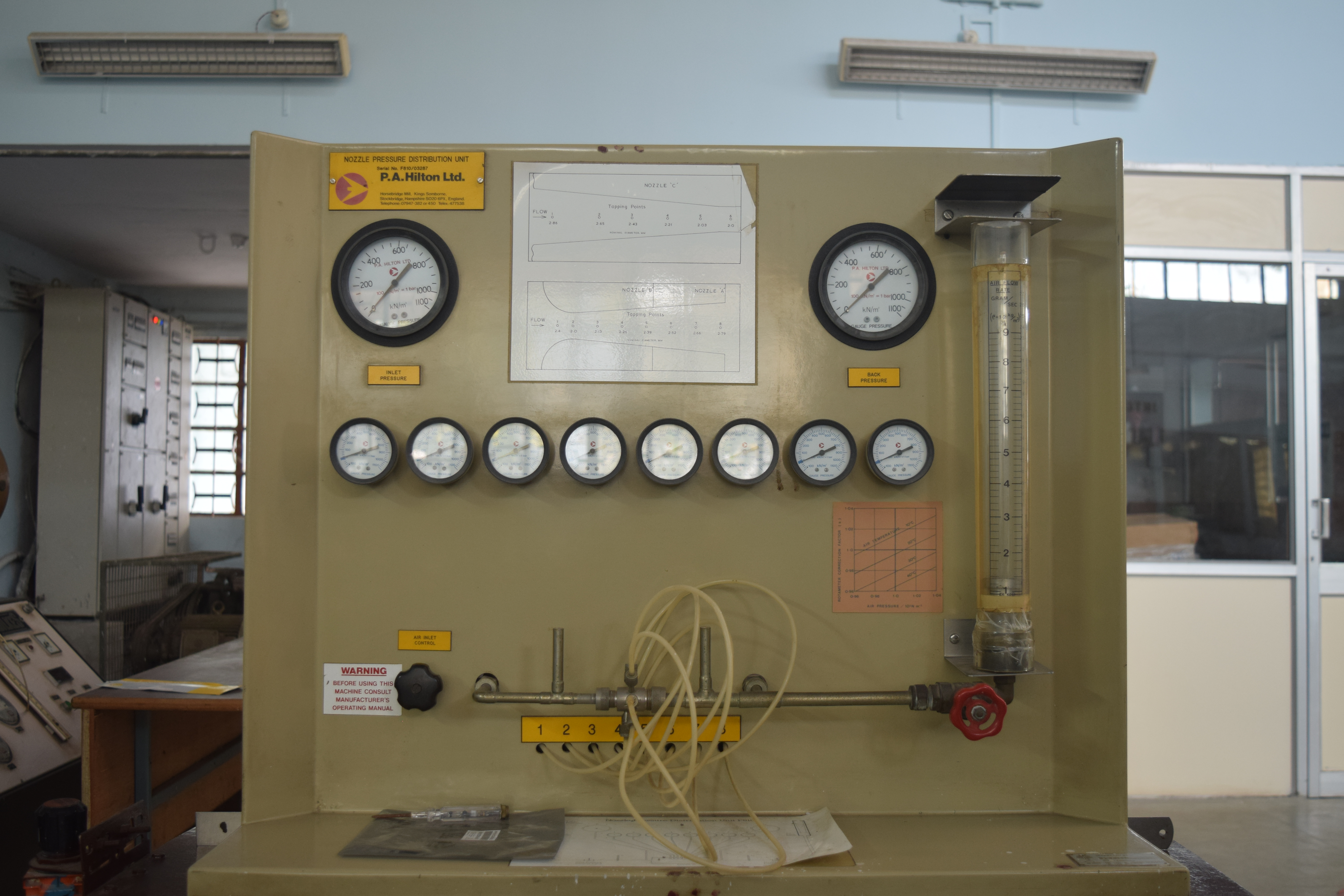

Nozzle Pressure Distribution Unit

- Investigation of the relationship between inlet pressure and mass flow rate

- Investigation of the relationship between outlet pressure and mass flow rate

- Visual demonstration of under expansion and over expansion with re-compression (shock wave)

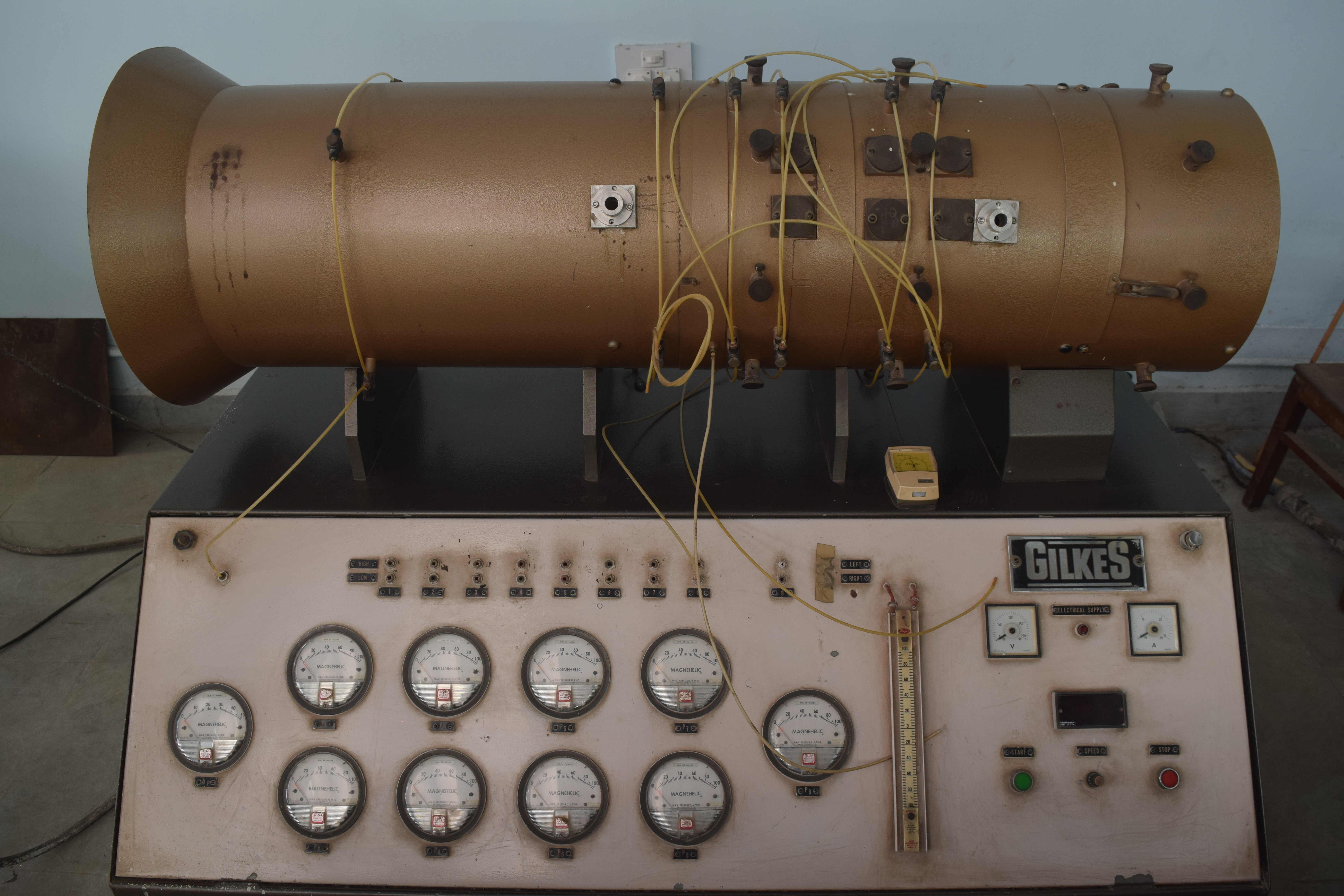

Axial Flow Fan Unit

- Measurement of Fan static overall pressure rise and Rotor static pressure rise

- Work ratio can be found out

- Mechanical power can be derived

- Electrical power can be calculated from the voltmeter & ammeter reading

- Fan overall efficiency can be determined

Centrifugal Fan Unit

- Provision of fitting forward guide vanes, radial guide vanes and backward guide vanes

- A standard nozzle is fitted to the fan inlet and diffuser as well

- The flow rate and pressure rise across the fan blade can be measured

Faculties

- Amardip Ghosh

- Ratan Joarder

- Srinibas Karmakar(Lab In-Charge)

- Chetankumar Sureshbhai Mistry